The activity, in the Parma and Angri seats, focuses on the materials for rigid and flexible packaging and on the closing systems from a technological, analytical and hygienic-sanitary point of view.

The activity is developed in collaboration with the producers of materials, packaging manufacturers and end users with the main purpose of providing scientific, analytical, technical and regulatory tools to create safe packaging that guarantees the quality and the hygienic-sanitary properties of the food product for its entire commercial life.

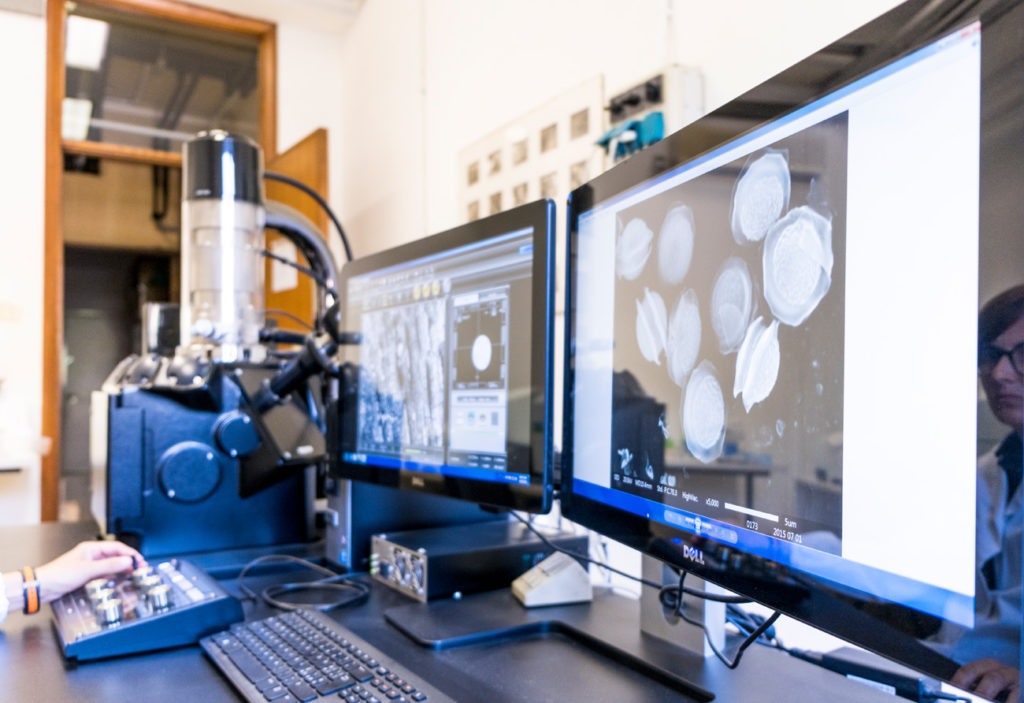

The research activity, carried out also in collaboration with research centres and universities at an international level, concerns the development and the application of innovative materials and coatings, of natural origin, the shelf life improvement of new packaging/food systems also as a function of process and storage conditions and emerging issues related to the health safety of contact materials and to environmental impact.

The consulting activity in the laboratory or directly in the company concerns technological issues in the use of packaging, such as the compliance with legal requirements and purchase specifications.